Solutions

Sotway

Sotway

Investments made in transformation processes that start without determining the goals and needs often fail to yield the desired results, the return on investment takes a long time and employees cannot adapt to this process, thus productivity decreases.

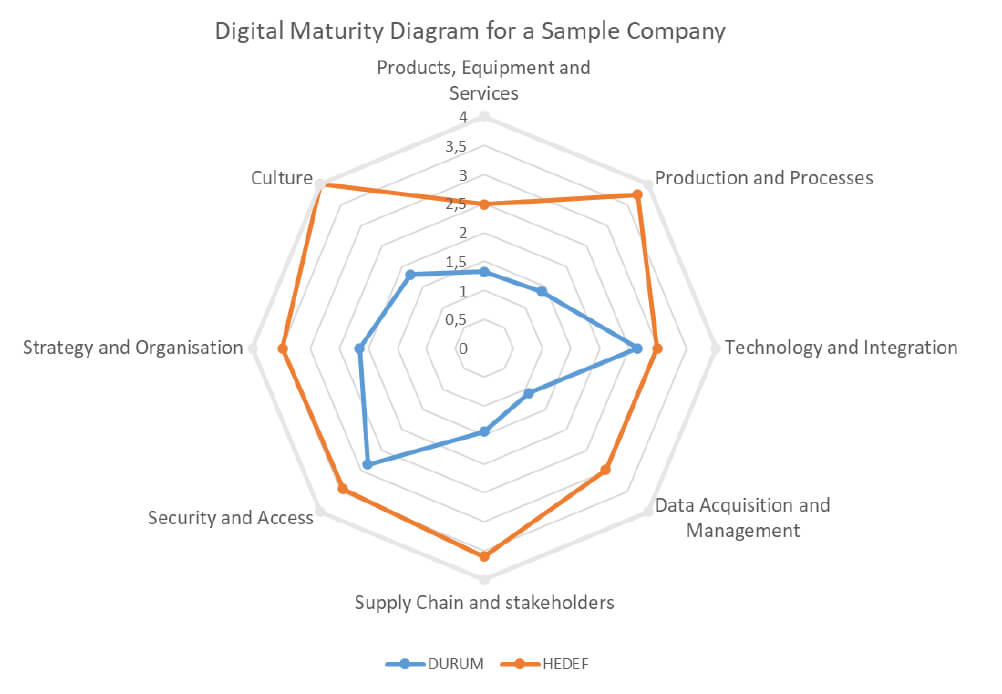

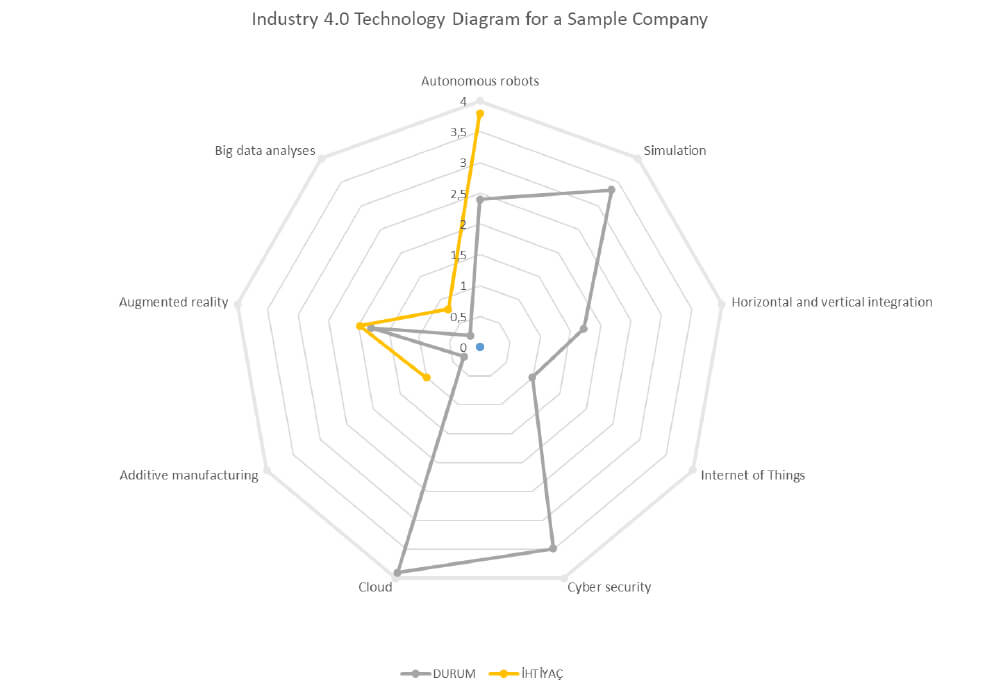

In addition to showing you your current digital maturity score, the Industrial Maturity Test and Roadmap determination study offers you your technology needs, transformation target scores and the roadmap you need to follow to meet your needs and achieve your goals as a total solution.

The Industry Maturity Test and Roadmap Determination Test has been created based on more than 150 indexed academic publications, industry 4.0 maturity models and papers accepted in the literature, with more than 20 years of industry experience.

Investments made in transformation processes that start without determining the goals and needs often fail to yield the desired results, the return on investment takes a long time and employees cannot adapt to this process, thus productivity decreases.

In addition to showing you your current digital maturity score, the Industrial Maturity Test and Roadmap determination study offers you your technology needs, transformation target scores and the roadmap you need to follow to meet your needs and achieve your goals as a total solution.

The Industry Maturity Test and Roadmap Determination Test has been created based on more than 150 indexed academic publications, industry 4.0 maturity models and papers accepted in the literature, with more than 20 years of industry experience.

Assessment Axes

The Industrial Maturity Test determines your digital maturity level and targets on eight axes, your level of use of industry 4.0 technologies and your needs on nine axes, your current status and needs regarding package programmes and edge technologies on 25 axes, and your current status of lean production on 14 axes. The test is face-to-face and it is expected to answer at least 214 questions. The current situation and target scores for each axis are determined by weighted average (ranking) method and the road map proposal to be followed to achieve the targets is prioritised using multi-criteria decision-making methods.

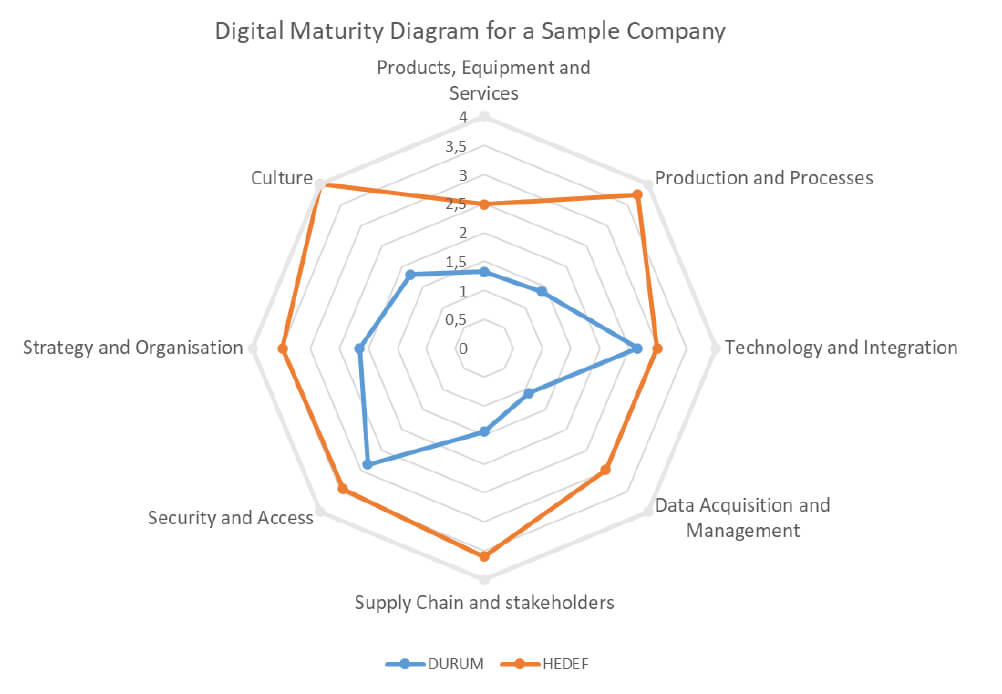

The axes where your digital maturity level and targets will be determined are as follows: Products and Services, Production and Processes, Technology and Integration, Data Acquisition and Management, Supply Chain and Stakeholders, Security and Access, Strategy, Human Resources.

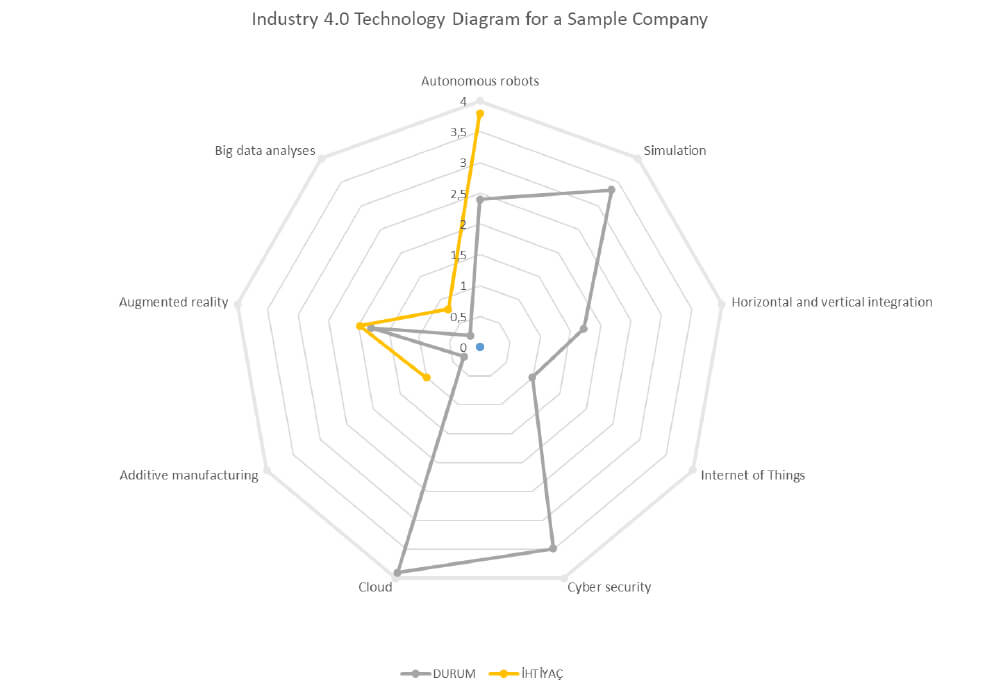

The axes where your Industry 4.0 technologies usage levels and needs will be determined are as follows: Autonomous Robots, Big Data Analytics, Augmented Reality, Additive Manufacturing, Internet of Things, Cyber Security, Cloud, Simulation, Horizontal and Vertical Integration.

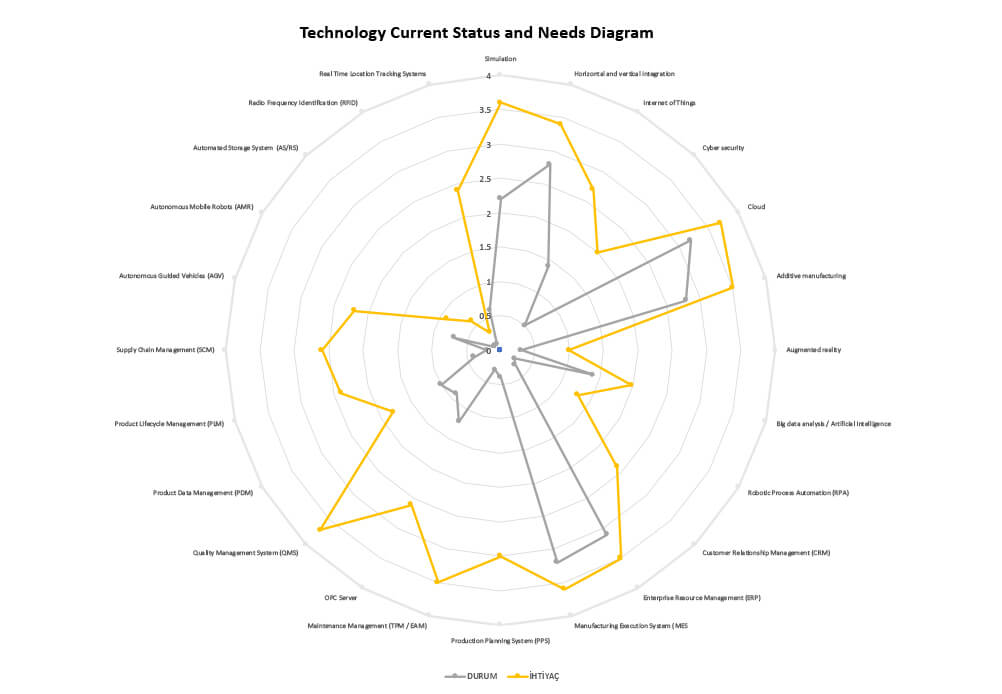

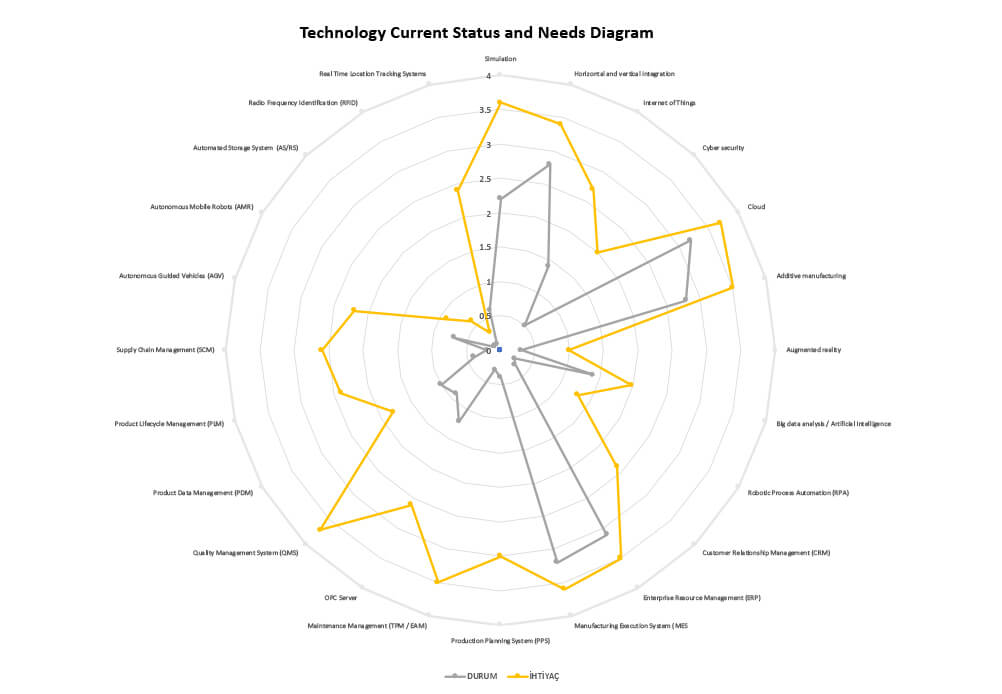

The axes to determine the current situation and your needs regarding package programmes and edge technologies are as follows: Robotic Process Automation (RPA), Customer Relationship Management (CRM), Enterprise Resource Management (ERP), Manufacturing Execution System (MES), Production Planning System (PPS), Maintenance Management (TPM / EAM), OPC Server, Quality Management System (QMS), Product Data Management (PDM), Product Lifecycle Management (PLM), Supply Chain Management (SCM), Autonomous Guided Vehicles (AGV), Autonomous Mobile Robots (AMR), Automated Storage System (AS/RS), Radio Frequency Identification (RFID), Real Time Location Tracking Systems, Autonomous robots, Simulation, Horizontal and vertical integration, Internet of Things, Cyber security, Cloud, Additive manufacturing, Augmented reality, Big data analysis / Artificial Intelligence

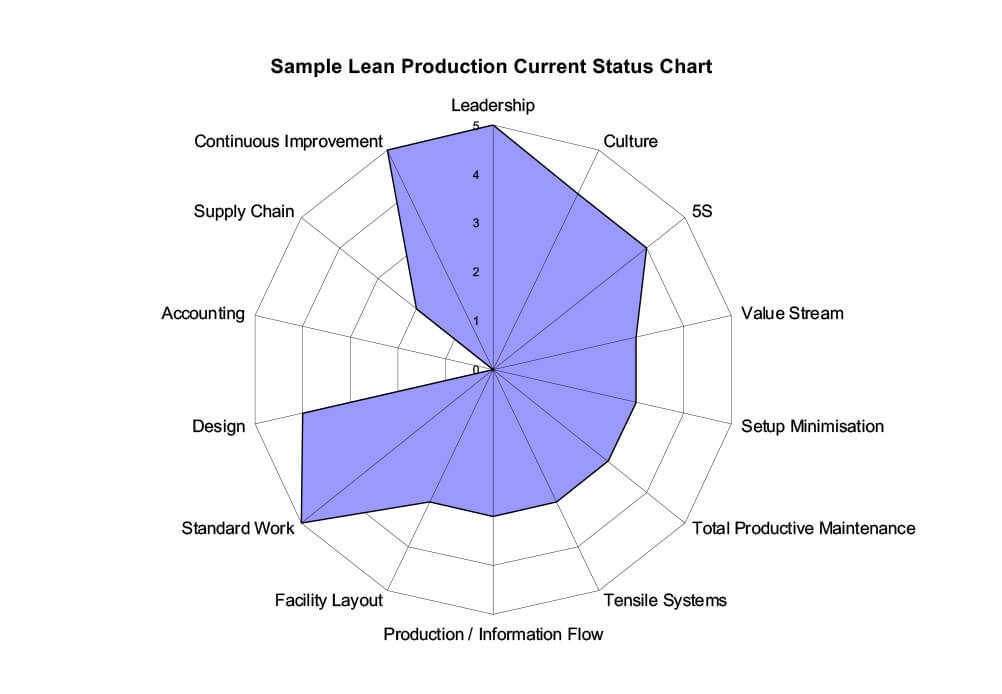

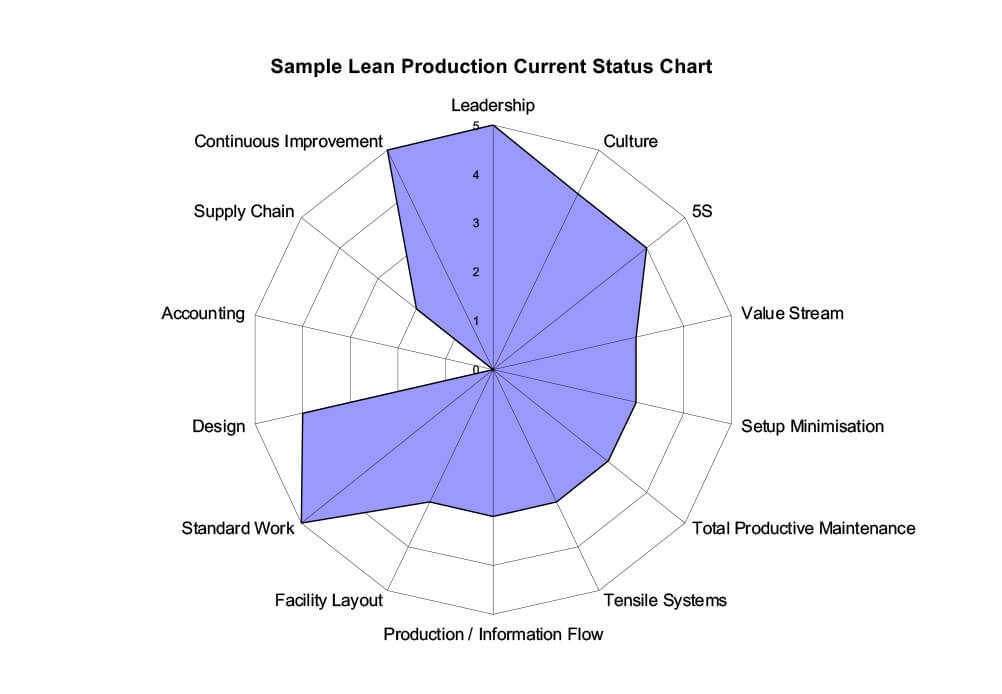

The axes that will determine your lean production maturity level are as follows: Leadership, culture, 5s, value stream, setup reduction, total productive maintenance, pull systems, production/information flow, plant layout, standard work, design, accounting, supply chain, continuous improvement, 3M.

The current situation is analysed in the 15 axes that can be considered as the basic axes of lean listed above and what needs to be done in the next steps is described.

Conclusion

As a result of the Industrial Maturity Test, a road map to be followed for each question, a needs analysis for all technologies and field observations are presented. Priority projects (3-5 projects) proposed to be realised by the company are examined in detail. It is explained why the project should be realised, how it will be realised, what benefits will be provided, how much effort will be spent and what kind of gain is expected. A generic project plan is delivered to the customer.

Assessment Axes

The Industrial Maturity Test determines your digital maturity level and targets on eight axes, your level of use of industry 4.0 technologies and your needs on nine axes, your current status and needs regarding package programmes and edge technologies on 25 axes, and your current status of lean production on 14 axes. The test is face-to-face and it is expected to answer at least 214 questions. The current situation and target scores for each axis are determined by weighted average (ranking) method and the road map proposal to be followed to achieve the targets is prioritised using multi-criteria decision-making methods.

The axes where your digital maturity level and targets will be determined are as follows: Products and Services, Production and Processes, Technology and Integration, Data Acquisition and Management, Supply Chain and Stakeholders, Security and Access, Strategy, Human Resources.

The axes where your Industry 4.0 technologies usage levels and needs will be determined are as follows: Autonomous Robots, Big Data Analytics, Augmented Reality, Additive Manufacturing, Internet of Things, Cyber Security, Cloud, Simulation, Horizontal and Vertical Integration.

The axes to determine the current situation and your needs regarding package programmes and edge technologies are as follows: Robotic Process Automation (RPA), Customer Relationship Management (CRM), Enterprise Resource Management (ERP), Manufacturing Execution System (MES), Production Planning System (PPS), Maintenance Management (TPM / EAM), OPC Server, Quality Management System (QMS), Product Data Management (PDM), Product Lifecycle Management (PLM), Supply Chain Management (SCM), Autonomous Guided Vehicles (AGV), Autonomous Mobile Robots (AMR), Automated Storage System (AS/RS), Radio Frequency Identification (RFID), Real Time Location Tracking Systems, Autonomous robots, Simulation, Horizontal and vertical integration, Internet of Things, Cyber security, Cloud, Additive manufacturing, Augmented reality, Big data analysis / Artificial Intelligence

The axes that will determine your lean production maturity level are as follows: Leadership, culture, 5s, value stream, setup reduction, total productive maintenance, pull systems, production/information flow, plant layout, standard work, design, accounting, supply chain, continuous improvement, 3M.

The current situation is analysed in the 15 axes that can be considered as the basic axes of lean listed above and what needs to be done in the next steps is described.

Conclusion

As a result of the Industrial Maturity Test, a road map to be followed for each question, a needs analysis for all technologies and field observations are presented. Priority projects (3-5 projects) proposed to be realised by the company are examined in detail. It is explained why the project should be realised, how it will be realised, what benefits will be provided, how much effort will be spent and what kind of gain is expected. A generic project plan is delivered to the customer.

Contact Us

We are just

a message away!

For information about our company and services, please fill out the form on the side to reach us.

Our consultants will get in touch with you as soon as possible.

Contact Form

Contact Us

We are just a message away!

For information about our company and services, please fill out the form on the side to reach us. Our consultants will get in touch with you as soon as possible.